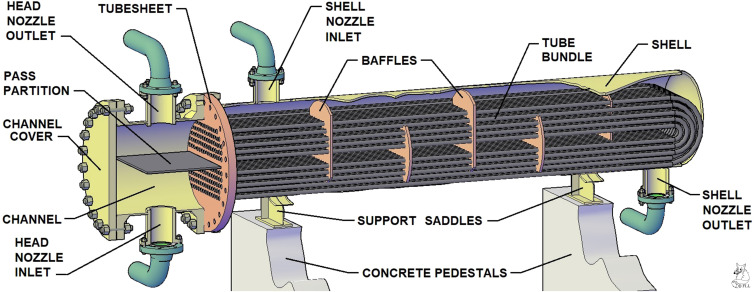

What is Shell and Tube heat Exchanger

How Does It Work ?

A shell and tube heat exchanger is a class of industrial heat exchanger designed for efficient heat transfer between two fluids.

It is the most widely used heat exchanger in oil refineries and large chemical plants and is suitable for higher pressure applications.

Fluid separation: A shell and tube heat exchanger separates the two fluids into two pathways: the "tube side" and the "shell side".

Tube-side flow: The first fluid, usually the one with higher pressure or greater corrosiveness, flows inside a bundle of tubes.

Shell-side flow: The second fluid flows over the outside of the tube bundle, through the shell.

Matrix Co. offers design and supply of shell and tube heat exchanger with all material process.

Carbon steel,Low Alloy Steel,Stainless steel,Duplex Stainless Steel,Copper and Copper Alloys,Copper-Nickel Alloys,Nickel,Nickel Alloys,Titanium.

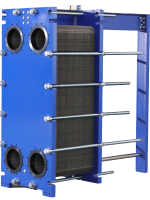

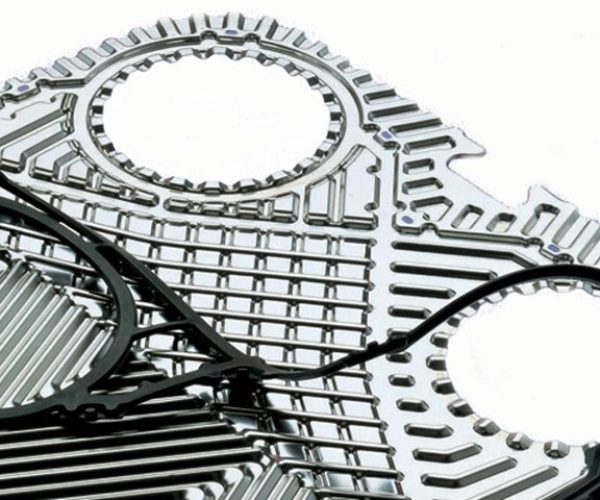

Gasketed Plate and Frame Heat Exchanger Advantages of Gasketed Plate Heat Exchanger

Maximize Efficiency with

Gasketed Plate

and Frame Heat Exchangers

Matrix Company’s gasketed plate and frame heat exchangers are engineered to deliver high-efficiency thermal performance across a wide range of industrial sectors. From oil and gas to chemical processing and manufacturing, our systems are built to perform reliably—even in the most demanding environments.

What distinguishes Matrix is our unwavering commitment to precision and durability. Each unit is constructed using premium-grade plates and gaskets, designed to withstand fluctuating pressures and extreme temperatures. Whether you're evaluating different gasket types or seeking a long-term solution for your heat transfer needs, Matrix offers customizable systems that boost efficiency, minimize downtime, and adapt seamlessly to your operational requirements.

Advantages of Shell and Tube heat Exchanger