What is open cooling tower

How Does It Work ?

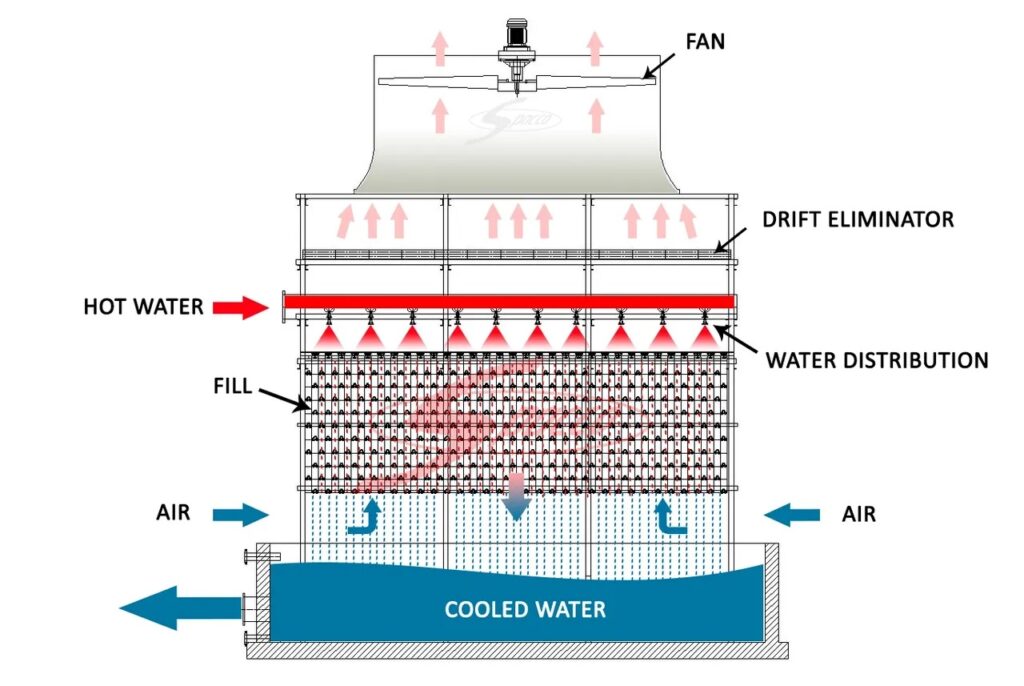

Open cooling towers discharge heat from water-cooled systems into the atmosphere.

The hot process water is distributed over a fill pack (heat transfer media) to interface with air blown by a fan through the cooling tower.

During this evaporative cooling, a small part of the water evaporates while cooling the remaining process water.

Open cooling towers have two designs cross flow and counter flow with several shapes of working techniques Induced draft - Forced Draft - Natural Draft

Matrix Co. offers design and supply most types of open cooling towers with FRP -Galv.Steel - Stainless steel material designed to meet the client requirements of water quality, air quality and space.

Gasketed Plate and Frame Heat Exchanger Advantages of Gasketed Plate Heat Exchanger

Maximize Efficiency with

Gasketed Plate

and Frame Heat Exchangers

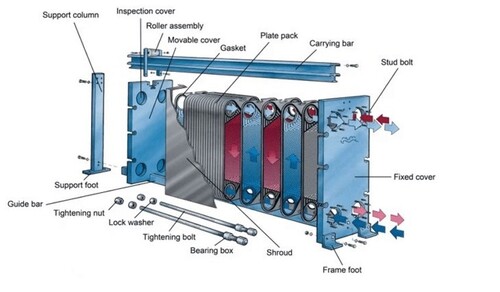

Matrix Company’s gasketed plate and frame heat exchangers are engineered to deliver high-efficiency thermal performance across a wide range of industrial sectors. From oil and gas to chemical processing and manufacturing, our systems are built to perform reliably—even in the most demanding environments.

What distinguishes Matrix is our unwavering commitment to precision and durability. Each unit is constructed using premium-grade plates and gaskets, designed to withstand fluctuating pressures and extreme temperatures. Whether you're evaluating different gasket types or seeking a long-term solution for your heat transfer needs, Matrix offers customizable systems that boost efficiency, minimize downtime, and adapt seamlessly to your operational requirements.

Advantages of open cooling tower

• High cooling efficiency

• Lower Initial Cost

• Energy efficiency

• Low Process temperatures can reach up to wet bulb temperature

• Small footprint

• Low maintenance cost

• Deal with all of water quality

Product Feature of Matrix Plate and Frame Heat Exchanger

Recommended Applications Of Gasketed Plate Heat

Exchanger

For a wide range of industrial applications involving heating, cooling, evaporation, and condensation, Matrix Company delivers custom-designed solutions. We supply various types of heat exchangers and fluid handling equipment—including gaskets, welded, and brazed plate heat exchangers—helping factories and industrial clients achieve optimal thermal performance, improved energy efficiency, and long-term operational reliability.

Energy and Power

Chemicals

Food and Beverage

Steel

Industrial Applications

Fertilizers

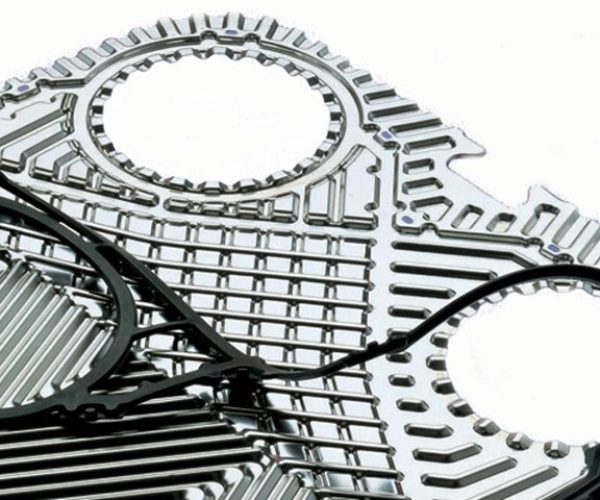

Apart from plate heat exchangers, Matrix Company also supplies a wide range of non-OEM replacement spare parts such as plates and gaskets compatible with major global brands—all at competitive prices. Our inventory is tailored to meet the needs of industrial clients seeking cost-effective, high-quality solutions. Explore our product catalog today!

Are you looking for cost-saving PHE replacement spare parts?

Matrix supplies non-OEM plate heat exchanger

spare parts that are fully compatible with PHEs of all brands.