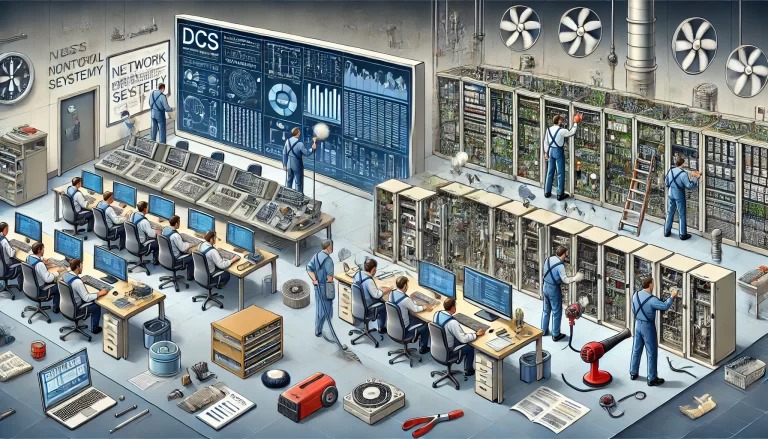

What is Control Panel and DCS System

How Does It Work ?

A control panel is a physical or software-based assembly of components for monitoring and controlling machinery or processes,

Whereas a Distributed Control System (DCS) is a sophisticated, plant-wide architecture that uses multiple, interconnected, autonomous controllers to manage complex, large-scale industrial processes in real-time.

While a simple control panel might manage a single machine or process, a DCS is designed for entire factories or plants, providing comprehensive, integrated, and reliable control through a distributed network of controllers, operator stations, and data historians.

Advantages of Control Panel and DCS System

Automatic Monitoring.Control panels continuously monitor system parameters, detecting malfunctions and heading off potential damage before it becomes serious.

Emergency Shutoffs.These panels can quickly shut down a system to prevent fires, equipment damage, and other threats.

• Optimized Operations.Control panels monitor and adjust processes to ensure equipment runs efficiently, preventing wasted energy and reducing operating costs.

• Reduced Downtime.By catchinga minor faults early, control panels prevent breakdowns and expensive repairs, ensuring continuous operation.

• Integrated Safety Systems.DCS platforms often include certified safety systems to ensure compliance and protect assets and personnel